Shuttering Plywood vs Film Faced Plywood: In construction activities—be it residential buildings, commercial building complexes, or big infrastructure projects—the role of formwork plywood cannot be understated. The hardness, smoothness, and re-usability of shuttering plywood can directly influence the quality of finish of the concrete and also overall project cost.

Table of Contents

What is Shuttering Plywood?

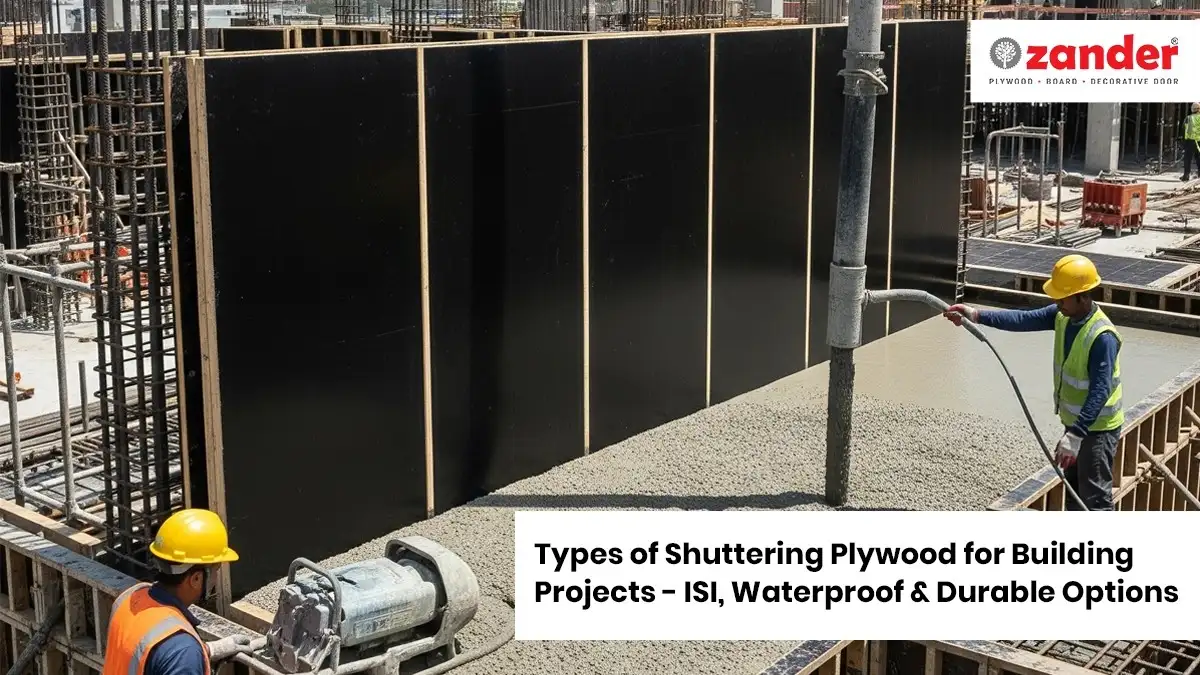

Shuttering plywood is a structurally designed plywood specifically for construction purposes to support wet concrete until set and strong enough. In contrast to standard plywood employed in interior works, shuttering plywood is produced with high-density wood and bonded with powerful adhesives (usually phenolic resins) for resisting heavy loads and moisture.

Key features of shuttering plywood:

- Produced from hardwood or eucalypty veneers.

- Has heavy loading capacity.

- Available in waterproof grades such as BWP (Boiling Water Proof).

- Comes in a range of thicknesses (12mm, 18mm, etc.).

- Reusable multiple times (quality dependent).

Waterproof shuttering plywood is the preferred choice for builders due to long-term durability, particularly where moisture levels are high.

What is Film Faced Shuttering Plywood?

Film faced shuttering plywood is a superior grade of shuttering plywood, treated with a unique phenolic or plastic film on both sides. This film offers a high surface finish to concrete casting, low water absorption, and extended life to the plywood.

Key features of film faced plywood:

- Glossy, smooth surface provides high-end finishing to concrete.

- High level of waterproofing over conventional shuttering plywood.

- Resistance to abrasion, chemicals, and water is very high.

- Reusable 20–30 times under proper handling.

- Supplied in thicknesses between 12mm and 21mm.

Also Read: Top 10 ISI Certified Flush Door Brands in India

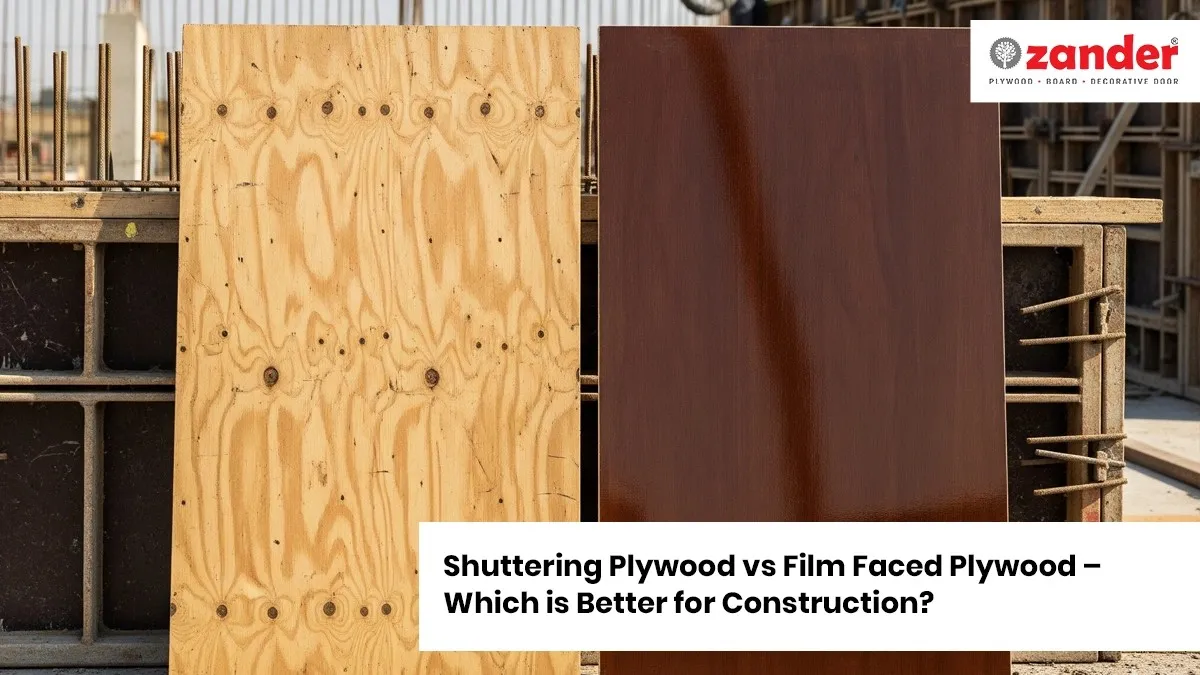

Shuttering Plywood vs Film Faced Plywood – The Core Difference

Let’s break down the main differences between the two:

| Feature | Shuttering Plywood | Film Faced Shuttering Plywood |

|---|---|---|

| Surface Finish | Rough, requires extra plastering | Smooth, needs little to no plastering |

| Water Resistance | Limited, unless high-grade waterproof shuttering plywood is used | Excellent, due to phenolic film coating |

| Durability & Reuse | 5–10 uses (depending on quality) | 20–30 uses with proper care |

| Cost | More affordable upfront | Higher cost, but more cost-effective in long run |

| Concrete Output | May leave uneven surface | Produces shiny, premium finish |

| Best Use | Small projects, low-budget works | Large projects, premium finish required |

So, the major advantage of film – faced shuttering plywood lies in its longevity, waterproof nature, and smooth finish.

Why Choosing the Right Plywood Matters in Construction

Builders tend to underestimate the significance of choosing the best plywood for use in concrete shuttering, but this is why it’s important:

- Quality of Concrete Surface: Better plywood saves on plastering and finishing expenditure.

- Structural Safety: Robust shuttering plywood avoids bulging or collapse while concreting.

- Project Cost Effectiveness: Long-lasting plywood with greater reusability saves in long-term costs.

- Time Savings: Finish of smooth concrete saves labor and curing time.

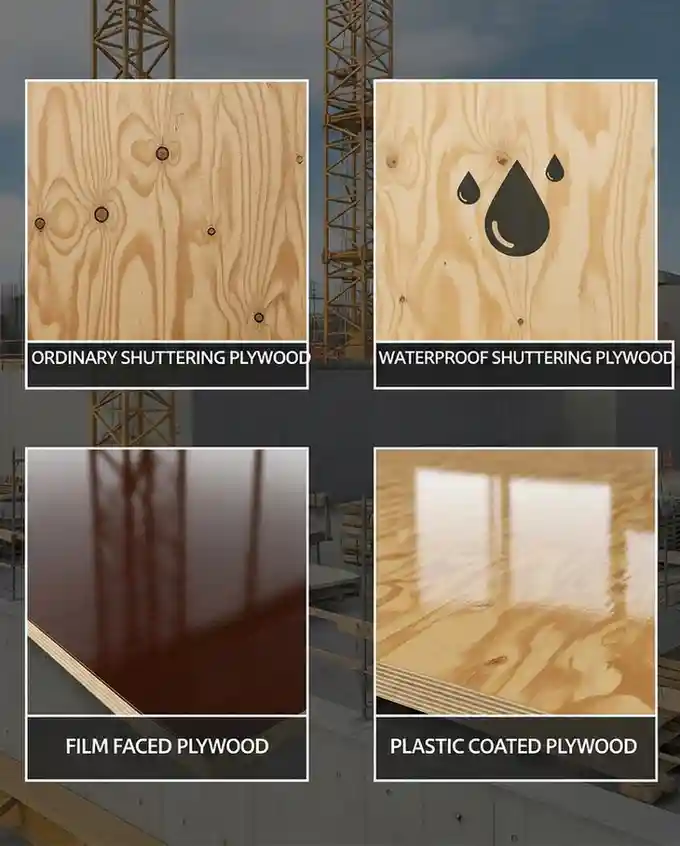

Types of Shuttering Plywood

Before making a decision between shuttering plywood and film faced plywood, it is essential to know the types of common ones available:

- Ordinary Shuttering Plywood – Standard quality, cheap, less reusability.

- Waterproof Shuttering Plywood (BWP Grade) – Higher strength, best for places exposed to water.

- Film Faced Shuttering Plywood – High quality with high reusability and level surface.

- Plastic Coated Plywood – Uncommon but useful; even better waterproofing than film faced.

Of these, the most widely used options in India are waterproof shuttering plywood and Reusable plywood for construction, depending on project size.

Pros and Cons of Shuttering Plywood

Advantages of Shuttering Plywood

- Affordable and Widely Available:

Shuttering plywood is among the most economical in the range of shuttering plywood available in the market. It’s readily available all over India and makes for a good cost-effective option for contractors employed on small- to medium-scale projects. - Suitable for General Construction Needs:

If it is projects such as low-rise buildings, boundary walls, or small residential houses that you are dealing with, shuttering plywood is sufficient in its load-bearing strength to prevent the concrete from spilling out. It is mostly preferred when no glossy or high-end concrete finish is needed. - Good Load-Bearing Strength:

Though not as strong as Black film faced plywood, standard shuttering plywood is still durable enough to withstand concrete pressure during pouring. Many builders use waterproof shuttering plywood (BWP grade) to add extra resistance against moisture and enhance life.

Disadvantages of Shuttering Plywood

- Uneven Concrete Surface Finish:

One of the major disadvantages of plain shuttering plywood is that it yields a rough concrete finish. This implies added plastering or finishing, which adds to labor expense as well as construction time. - Limited Reuse Value:

While movie exposed shuttering plywood can be recycled up to 20–30 times, regular shuttering plywood will last only 5–10 uses depending on their quality. Builders who want to save money in the long term find this reduced reuse value a significant drawback. - Moderate Water Resistance:

Unless you choose specifically waterproof shuttering plywood (BWP grade), the sheets can swell or become weak when they come in contact with water. This shortens the life of the plywood and can also weaken the strength of the formwork.

Pros and Cons of Film Faced Shuttering Plywood

Advantages of Film Faced Plywood

- Smooth and Premium Concrete Finish:

Due to the phenolic film coating on either side, film faced shuttering plywood gives a glossy and smooth finish to the concrete surface. This saves or even eliminates plastering, thereby cutting down on time, material, and costs. For contractors looking for high-end finishes, this is the best plywood for concrete shuttering. - Superior Waterproofing and Durability:

The phenolic film renders this plywood extremely resistant to chemicals, rain, and moisture. The film faced shuttering plywood is not prone to swelling easily when wet as compared to regular plywood. Therefore, it is suited for use in wet or humid environments. - High Strength and Load-Bearing Capacity:

As it is made from high-density hardwood veneers and glued using waterproof adhesives, film faced plywood withstands the high bearing capacity of reinforced concrete structures. Therefore, film faced plywood is a reliable option for bridges, flyovers, and skyscrapers. - Long-Term Cost Savings (High Reusability):

Though it is more expensive at the outset, film faced shuttering plywood can be recycled up to 20–30 times provided proper care is taken. Thus, it is very cost-saving in the long term, particularly for contractors who work on several different projects.

Disadvantages of Film Faced Plywood

- Higher Initial Cost:

Compared to other forms of shuttering plywood, film faced plywood is more costly per sheet. For small builders or one-off sites, the greater initial cost may not always be possible. - Requires Careful Handling:

To ensure maximum reusability, film faced plywood should be handled carefully. Improper handling can cause edges to be damaged and decrease its life, thus making it less economical.

Which One Should You Choose?

The reply is based on your type of project, budget, and long-term benefits:

- If you are working on small residential projects or need an inexpensive short-term solution → use plain shuttering plywood or water proof shuttering plywood.

- If you are working on big commercial projects, bridges, or upmarket constructions where surface finish and long-term cost savings are important, film faced shuttering plywood is a better option.

That is, if budget is the top priority, shuttering plywood does the trick. However, if you wish for quality, durability, and top-shelf finish, film faced wins.

Cost Factor – Is Film Faced Worth It?

Many contractors hesitate to buy film faced plywood because of its higher price per sheet. But let’s do a quick calculation:

- Ordinary shuttering plywood: Average cost ₹55–65 per sq. ft., usable 5–8 times.

- Film faced shuttering plywood: Average cost ₹80–100 per sq. ft., usable 20–30 times.

Over time, film faced plywood provides a lower cost per usage and also reduces plastering expenses. So while the upfront cost is higher, it is more economical in large projects.

How to Identify Good Quality Shuttering Plywood

To ensure you’re buying the right material, check for:

- ISI Certification (IS 4990 grade).

- Even thickness and strong edges.

- No visible gaps in the layers.

- Smooth finish and waterproof coating.

- Reputed brands like Century Ply, Greenply, Zander Ply etc.

Practical Tips for Using Shuttering Plywood

- Always apply shuttering oil before pouring concrete to increase life.

- Avoid nails; use clamps to reduce damage.

- Store plywood sheets in a dry area after use.

- Clean the surface properly before reuse.

Also Read: Top 10 Plywood manufacturers of India

FAQs

Q1. Which is better – Shuttering Plywood or Film Faced Plywood?

Film faced shuttering plywood is preferable for most major building works. It is water-resistant, reusable 20–30 times, and provides a smooth concrete surface with a saving in plastering expenses. Shuttering plywood is cheaper but not reusable much.

Q2. What is the best plywood for concrete shuttering?

Film faced shuttering plywood is the most suitable plywood for concrete shuttering due to its durability, water resistance, and high-quality finish on premium concrete. In the case of small-scale projects or limited budgets, waterproof shuttering plywood can also be used

Q3. Is film faced shuttering plywood waterproof?

Yes, 100% waterproof is film faced plywood. Both sides are protected by phenolic film coating, so no water can be absorbed by it, which makes it extremely durable even in rainy or moisture-rich environments.

Q4. How many times can shuttering plywood be reused?

Normal shuttering plywood can be used 5–10 times based on quality. Compared to this, film faced plywood can be used 20–30 times with proper care and storing.

Q5. What are the different types of shuttering plywood?

The most common types of shuttering plywood are:

1. Ordinary shuttering plywood (basic, budget).

2. Waterproof shuttering plywood (BWP grade, strong).

3. Film faced plywood (finish quality, reusable).

4.Plastic coated shuttering plywood (rare and very long-lasting).

Q6. Why should builders choose film faced plywood?

Builders opt for film faced plywood as it is cost-saving in the long run, gives a shiny concrete finish, and is water damage resistant. While it costs more initially, it’s more cost-effective because of repeated usage.

Q7. Which brands offer the best shuttering plywood in India?

Popular brands include Century Ply, Greenply, and Zander Ply, all known for high-quality waterproof and Long-lasting plywood for construction suitable for concrete formwork.

Final Thoughts

When comparing shuttering plywood vs film faced plywood, the choice ultimately depends on your project needs:

- For budget-friendly construction or smaller works, waterproof shuttering plywood is usually sufficient.

- For long-term, large-scale, or high quality projects, film faced plywood investment is a wiser idea since it provides durability, smooth concrete finish, and greater reusability.

Simply put, for the best plywood for concrete shuttering that offers an optimal balance of cost-effectiveness, strength, and quality finish, film faced plywood unequivocally provides the best value.