Kitchen cabinets swelling again? You’re probably using the wrong plywood.

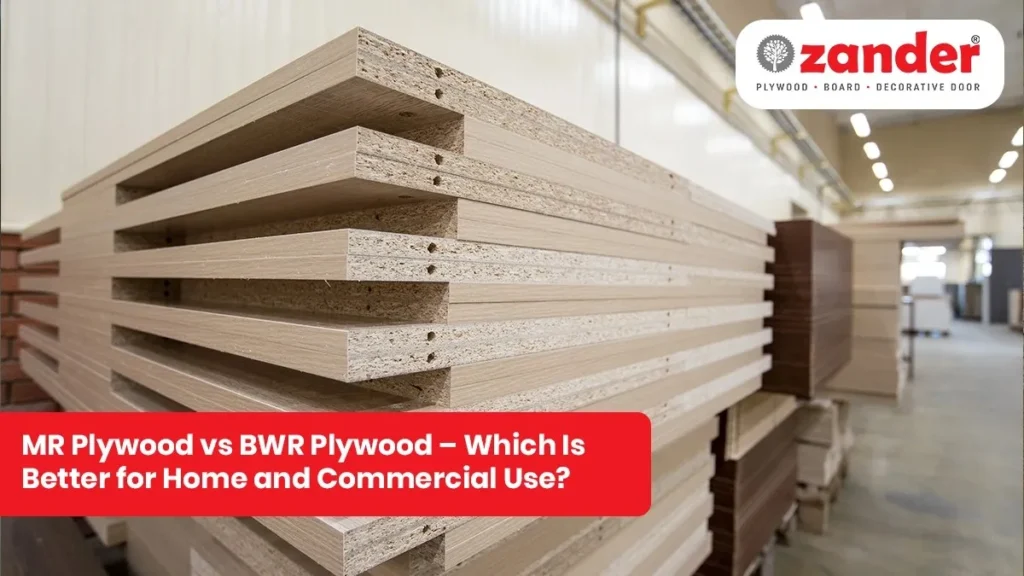

MR Plywood vs BWR Plywood: Choosing the right plywood is more than just a design decision—it’s about durability, safety, and value for your money. In this article, we’ll simplify the ongoing debate: MR Plywood vs BWR Plywood. With growing awareness about moisture resistant plywood uses, more homeowners and commercial space planners are trying to understand which plywood performs best in different zones of a home or workspace.

Table of Contents

What is MR Plywood?

MR Plywood or Moisture Resistant plywood is a widely used interior-grade plywood utilized for domestic and commercial applications. Despite its name, MR plywood is not water-resistant but moisture- and humidity-resistant under normal dry indoor conditions.

- Glue applied: Urea-formaldehyde resin (for internal use)

- ISI Grade: IS:303 (specification for interior-grade plywood)

This plywood works ideal for interior rooms where humidity is occasional but there is no direct exposure to water. Consider areas that are dry most of the time but can face damp air—such as bedrooms during monsoons or offices with AC.

Common Moisture Resistant Plywood Uses:

- Bedroom wardrobes: Protects clothes and linens from small moisture.

- Wall paneling: Light and decor-friendly for contemporary interiors.

- Office furniture: Strong enough for desks, drawers, and cabinets.

- Bookshelves: Shields paper from warping due to humidity.

- TV units and media walls: Suitable for decorative, load-carrying panels.

Because of its cost-effectiveness and moderate durability, MR plywood is a go-to choice for dry interior zones in both homes and workspaces.

Also Read : Commercial Plywood vs Marine Plywood: Which One Is Best for Wet Areas, Cost & Durability?

What is BWR Plywood?

BWR Plywood, or Boiling Water Resistant plywood, is designed to resist exposure for extended periods to moisture and humidity. It differs from MR plywood in that it employs phenol-formaldehyde resin, hence can be applied in semi-wet and damp conditions. It is among the most popular options when it comes to uses of Waterproof Plywood for Kitchen and Bathroom.

Advantages of BWR plywood

- High Bonding Strength: The phenol-formaldehyde adhesive provides BWR plywood excellent internal bonding, rendering it tougher than regular MR plywood.

- Boiling Water Resistance: It is capable of withstanding exposure to boiling water for up to 8 hours without delamination, which makes it perfectly suitable for wet areas with high moisture content.

- Excellent Moisture Resistance: Although not waterproofed completely like marine plywood, BWR plywood has water-resistance in bathrooms, under-sink locations, and steamy kitchens.

- Long-Term Durability: With care and proper sealing, it can last up to 10–15 years in semi-wet interiors.

- Pest Resistance: It provides good resistance to borer and termites, particularly if pre-treated, and thus is ideal for both domestic and commercial installations.

Where to Use BWR Plywood: Ideal Applications

Due to its semi-waterproof nature, BWR plywood is put to widespread application in spaces that are exposed to high humidity, steam, or unexpected splashes.

Best Uses in Waterproof plywood for home interiors:

- Modular Kitchens: BWR plywood is a stable, moisture-resistant foundation for kitchen cabinets, drawers, and overhead cabinets, particularly around sinks and stoves.

- Bathroom Vanities: Suitable for bathroom cabinets and storage cabinets, where it is exposed to steam and moisture on a regular basis.

- Laundry Rooms: Since washing machines and dryers add moisture to the atmosphere, BWR plywood also stops swelling or warping of storage shelves and countertops.

- Under-Sink Units: Area under sinks is subject to drips and moisture at all times—BWR works far better than MR in such a situation.

Best Uses in Semi-Outdoor & Commercial Spaces:

- Outdoor Furniture (Under Shade): BWR-plywood constructed patio furniture, balcony cabinets, and garden benches work satisfactorily if not exposed to open rain.

- Cafe and Restaurant Counters: Spills, steam, and water exposure are common here—BWR ensures longevity and less maintenance.

- Salon Storage Units: Hair salons use water all the time; BWR plywood does not warp or lose its structure.

- Gym and Locker Room Furniture: Frequent cleaning and humidity—BWR plywood will perform better than regular plywood in such arrangements

Side-by-Side Comparison: MR Plywood vs BWR Plywood

| Feature | MR Plywood | BWR Plywood |

|---|---|---|

| Water Resistance | Low (resists moisture only) | High (resists boiling water) |

| Glue Type | Urea-formaldehyde | Phenol-formaldehyde |

| Durability | Medium | High |

| Cost | Lower | Slightly higher |

| Ideal Use | Dry zones | Semi-wet zones |

| Indoor Use | Yes | Yes |

| Outdoor Use | No | Yes (sheltered only) |

| Lifespan | 5-7 years | 10-15 years |

| Maintenance | Easy | Easy |

| ISI Grade | IS:303 | IS:303 (higher bonding) |

So, MR Plywood vs BWR Plywood? It depends on the usage area and moisture exposure.

Where to Use MR Plywood in Home and Commercial Interiors

MR plywood or Moisture Resistant plywood is perfect for indoor use where water exposure is less but humidity is higher at times. Its low cost, simplicity of use, and good durability make it a favorite for numerous residential as well as commercial uses.

Residential Use of MR Plywood:

- Wardrobes in Bedrooms: Perfect for keeping clothes in dry bedrooms; MR plywood will not shrink or expand after some time.

- Bookshelves: Ideal for home libraries or study areas of children, providing a good load-bearing capacity for books.

- Wall Panels: Adds to the beauty of dry interior walls with a smooth surface and reasonable cost.

- TV Consoles and Units: Applications of moisture resistant plywood in living rooms are typical for entertainment areas where there is little moisture.

- Study Tables & Work Desks: Provides a good support and finish for dry areas such as bedroom or study room.

- False Ceilings: MR plywood is utilized in light ceiling systems in hallways or bedrooms and provides both design and strength.

Commercial Use of MR Plywood:

- Office Furniture: Desks, chairs, and file cabinets in dry offices are advantageously served by the cost-effectiveness of MR plywood.

- Reception Counters: Used often in lobbies and front desks where beauty and strength are necessary without exposure to water.

- Display Shelves: In showrooms, stores, and bookstores—perfect where there is no direct water exposure.

- Conference Tables & Partitions: Convenient for making office partitions or boardroom tables that don’t need to be waterproofed.

- Retail Fixtures: Excellent for mall kiosks or clothing display departments where appearance is important but moisture is regulated.

Ideal for moisture resistant plywood uses in zones that don’t come in direct contact with water but may face seasonal humidity.

Whether you’re designing a bedroom or furnishing an office, interior plywood like MR grade can serve you well in all dry and moderately humid spaces.

Also Read: Best Plywood for Modular Kitchen and Wardrobes in Ranchi

Durability Test: How MR and BWR Perform Over the Years

Let’s take real-life examples:

- A kitchen in Lucknow made of MR plywood—suited for dry spaces—began to swell and delaminate in a mere 3 years. Even though it is called moisture-resistant plywood, MR plywood cannot be used for high-humidity spaces such as kitchens that are subject to regular exposure to steam, leakage, and heat.

- Conversely, a bedroom in Delhi built using MR plywood remains intact for more than 6 years without any damage being visible, reasserting that applications of moisture resistant plywood are best restricted to dry indoor conditions like wardrobes, study units, and wall panels.

- Kitchens in wet cities such as Mumbai and Chennai, where exposure to water and moisture on a daily basis is unavoidable, show that BWR plywood benefits stand out in the long run. If well laminated and edge-sealed, BWR plywood has been tested and found to sustain high levels of moisture and boiling water exposure for over 10 years without warping or weakening.

This further establishes BWR plywood as the go-to waterproof plywood for kitchen and bathroom applications. Its high bonding strength and superior resistance to boiling water make it ideal for wet areas and high-humidity environments.

Price Comparison – MR vs BWR Plywood Costing in 2025

| Plywood Type | Avg Price (19mm Sheet) | Price per sq. ft. |

| MR Plywood | ₹70 – ₹90 | ₹2.8 – ₹3.5 |

| BWR Plywood | ₹90 – ₹125 | ₹3.5 – ₹5.0 |

Though BWR costs more, it provides more durability. For high-traffic or semi-wet areas, the extra cost is worth it.

Fake vs Original: How to Identify Authentic MR and BWR Plywood

Avoid falling for cheap duplicates labeled as “waterproof.”

Tips to identify:

- Check for ISI mark with code IS:303

- Look for batch number and manufacturer stamp

- Buy from trusted dealers or company showrooms

Customer Dilemma: MR or BWR? Choose Based on These 5 Factors

- Budget: MR is cheaper

- Moisture Exposure: BWR for wet zones

- Longevity Needed: BWR lasts longer

- Purpose: Wardrobe? MR. Kitchen? BWR.

- Professional Advice: Always consult your carpenter or interior expert

Expert Tips – What Carpenters and Interior Designers Recommend

“For kitchens, always go with BWR,” says Ramesh, a carpenter with 15 years experience.

“For wardrobes or bookshelves, MR works just fine,” shares Neha, an interior designer from Lucknow.

Interior professionals trust waterproof plywood for home interiors like BWR for areas with water or moisture.

When NOT to Use MR or BWR Plywood

While MR plywood and BWR plywood are popular choices for most interior applications, they do have their limits. It’s crucial to understand when not to use them—especially in extreme environments.

Not Suitable for Constant Wetness

If an area will be in constant contact with water, like:

- Exterior wall cladding exposed to rain

- Bathroom floors or shower enclosures

- Boat-building or dockyards

Then MR and BWR plywood are not waterproof enough to support such quantities of moisture. Although boiling water resistance is among BWR plywood benefits, it is still not ideal for subject to continuous water submersion.

What to use instead:

Marine Plywood – This is the final waterproof plywood to be used in kitchens and bathrooms in extreme applications. It meets IS:710 standards and is manufactured with high-grade phenol-formaldehyde resin and top-grade hardwood veneers, making it durable even for marine conditions.

Not Fire-Resistant

Using MR or BWR plywood in fire-sensitive environments like:

- Commercial kitchens

- Server rooms or data centers

- Electrical panel boards

…can be dangerous.

What to use instead:

Fire-Retardant Plywood – This specialty plywood is chemically treated to resist flames and slow down combustion. It’s a much safer option in fire-prone zones.

Other Specialized Plywood Alternatives

- Shuttering Plywood – For concrete formwork in construction

- Flexible Plywood – For curved furniture designs

- Calibrated Plywood – For uniform thickness in modular furniture

Summary: While moisture resistant plywood uses and BWR plywood advantages make them reliable for most interiors, avoid them for wet exteriors or fire zones. Instead, choose marine plywood or fire-retardant plywood where extreme durability is required.

Top Brands That Offer MR and BWR Plywood in India

Some of the top plywood manufacturers offering original MR and BWR grades:

- Greenply

- CenturyPly

- Kitply

- Austin Plywood

- Zander Plywood (for B2B and contractors)

Always buy from reputed sources to ensure product quality and durability.

Final Verdict: MR vs BWR Plywood – Which One Wins for You?

Let’s summarize:

- Home Interiors: MR for dry zones, BWR for semi-wet zones

- Commercial Interiors: Mostly BWR due to better durability

If budget allows, BWR plywood gives you peace of mind in kitchens, bathrooms, and more.

Call to Action: Before you buy, consult a trusted plywood dealer or interior professional.

Maintenance Tips to Extend the Life of MR and BWR Plywood

- Seal all edges of the plywood using edge bands or laminates

- Minimize direct contact with water where possible

- Clean with a damp or dry cloth on a regular basis

- Treat with anti-termite and anti-borer chemicals

Proper care can provide excellent performance from MR and BWR plywood alike.

Conclusion: Use MR or BWR depending on actual usage requirements. Uses of moisture resistant plywood and waterproof plywood for bathroom and kitchen will be a better decision for you than considering solely price.

Stay informed. Build smarter.

FAQs – MR vs BWR Plywood

1. Is MR plywood waterproof?

No, MR plywood is not waterproof but is moisture resistant. It is fine to use in dry spaces such as bedrooms or study rooms. For wet areas, use waterproof plywood such as BWR.

2. Can I use MR plywood in kitchen?

Application of MR plywood in the kitchen is not advisable as it does not support excessive moisture. The kitchen requires water-resistant plywood such as BWR for enhanced resilience. MR plywood can be used only for dry storage compartments.

3. What are the advantages of BWR plywood?

BWR plywood is resistant to boiling water and perfect for semi-wet spaces such as bathrooms and kitchens. It provides great bonding and withstands longer time in humid environments. The BWR plywood benefits make it perfect for domestic and industrial use.

4. Which plywood is best for bathroom furniture?

BWR plywood is most suitable for bathroom furniture because of its water resistance and durability. It can handle areas with high moisture well if sealed. For exposure to heavy water, marine plywood is also suitable.

5. Is BWR plywood good for commercial use?

Yes, BWR plywood is suitable for commercial purposes where durability and moisture matter. It’s perfect for restaurants, clinics, and salons. The applications of moisture-resistant plywood make it dependable for crowded areas.